Pelat baja karbon NM500

Katrangan Produk

| Jeneng Produk | Pelat Baja Karbon NM500 |

| Bahan | 4130, 4140, AISI4140, A516Gr70, A537C12, A572Gr50, A588GrB, A709Gr50, A633 D, A514, A517, AH36, API5L-B, 1E0650, 1E1006, 10CrMo9-10, BB41BF, BB503, Coet enB, DH36, EH36, P355GH, X52, X56, X60, X65, X70, Q460D, Q460, Q245R, Q295, Q345, Q390, Q420, Q550CFC, Q550D, SS400, S235, S235JR, A36, S235J0, S275JR, S275J0 S275J2,S275NL,S355K2,S355NL,S355JR,S355J0,S355J2,S355G2+N,S355J2C +N, SA283GrA, SA612M, SA387Gr11, SA387Gr22, SA387Gr5, SA387Gr11, SA285GrC, SM400A, SM490, SM520, SM570, St523, St37, StE355, StE460, SHT60, S690Q, S690QL, S890Q, S960Q, WH60, WH70, WH70Q, WQ590D, WQ690, WQ700, WQ890, WQ960, WDB620 |

| Permukaan | Dilapisi warna alami galvanis utawa disesuaikan |

| Teknik | digulung panas utawa digulung adhem |

| Aplikasi | Pelat baja NM500 minangka pelat baja tahan aus kanthi kekuatan dhuwur kanthi ketahanan aus sing dhuwur. Pelat baja tahan aus NM500 akeh digunakake ing mesin teknik, mesin perlindungan lingkungan, mesin metalurgi, abrasif, bantalan, lan bagean produk liyane. |

| Standar | DIN GB JIS BA AISI ASTM EN GOST etc. |

| Wektu pangiriman | Sajrone 7-15 dina kerja sawise nampa simpenan utawa L/C |

| Pengepakan ekspor | Paket strip baja utawa kemasan sing layak laut |

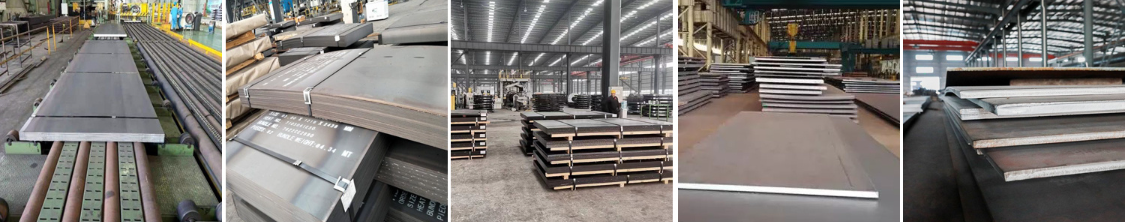

| Kapasitas | 250.000 ton/taun |

| Pambayaran | T/T/C, Western Union, lan liya-liyane. |

Wektu mimpin lan Pelabuhan

Kertas tahan banyu, lan strip baja dikemas. Paket Standar Ekspor Layak Laut. Cocok kanggo kabeh jinis transportasi, utawa miturut kabutuhan

Pelabuhan: Pelabuhan Qingdao utawa pelabuhan Tianjin

Wektu Pangiriman:

| Kuantitas (Ton) | 1 - 10 | 11 - 30 | 31 - 100 | >100 |

| Perkiraan Wektu (dina) | 15 | 15 | 15 | Kanggo dirembug |

Rincian Produk

Proses manufaktur

Proses manufaktur pelat baja karbon utamane kalebu langkah-langkah ing ngisor iki:

Peleburan: Nglebur bahan mentah kaya ta bijih wesi lan karbon dadi baja cair liwat tungku listrik utawa perapian terbuka.

Pengecoran terus-terusan: Nyuntikake baja cair menyang kristalisasi pengecoran terus-terusan, banjur didinginkan lan dipadatkan kanggo mbentuk bilet baja kanthi spesifikasi tartamtu.

Rolling: Billet baja diumpanake menyang rolling mill kanggo rolling, lan sawise pirang-pirang rolling pass, mbentuk plat baja kanthi kekandelan lan jembar tartamtu.

Pelurusan: Kanggo meluruskan pelat baja sing digulung supaya ora ana fenomena lentur lan bengkok.

Perawatan permukaan: Polesan, galvanisasi, pengecatan, lan perawatan permukaan liyane ditindakake ing pelat baja miturut kabutuhan kanggo ningkatake ketahanan korosi lan estetika.

| Jeneng Produk | Lembaran/Pelat Baja Karbon |

| Bahan | S235JR, S275JR, S355JR, A36, SS400, Q235, Q355, ST37, ST52, SPCC, SPHC, SPHT, DC01, DC03, lsp |

| Kekandelan | 0.1mm - 400mm |

| Jembar | 12.7mm - 3050mm |

| Dawane | 5800, 6000 utawa disesuaikan |

| Permukaan | Kulit ireng, pengawetan, pelumasan, galvanis, pengalengan, lan liya-liyane |

| Teknologi | Gulungan panas, Gulungan adhem, Pengawetan, galvanis, tinning |

| Standar | GB, GOST, ASTM, AISI, JIS, BS, DIN, EN |

| Wektu Pangiriman | Sajrone 7-15 dina kerja sawise nampa simpenan utawa L/C |

| Pengepakan Ekspor | Paket strip baja utawa kemasan sing layak laut |

| Kapasitas | 250.000 ton / taun |

| Pambayaran | T/T/C, Western Union, lan liya-liyane. |

| Jumlah Pesanan Minimal | 25 Ton |

Aplikasi

| Lapangan Aplikasi Pelat Baja Struktural Karbon ASTM A36 | |||||||

| bagean mesin | pigura | perlengkapan | pelat bantalan | tank-tank | tong sampah | pelat bantalan | tempaan |

| pelat dasar | gir | kamera | sprocket | jig | cincin | cithakan | perlengkapan |

| Pilihan Fabrikasi Pelat Baja ASTM A36 | |||||||

| mbengkongake adhem | pembentukan panas entheng | nonjok | mesin | pengelasan | mbengkongake adhem | pembentukan panas entheng | nonjok |

Amarga kekuwatane sing relatif apik, kemampuan mbentuk baja A36, lan kasunyatan manawa bisa dilas kanthi gampang, mula umume digunakake minangka baja struktural. Bisa ditemokake ing bangunan, jembatan, lan struktur skala gedhe liyane.

Iki digunakake ing konstruksi jembatan, bangunan, lan rig lenga sing dibaut, dipaku, utawa dilas.

Iki digunakake kanggo mbentuk tangki, wadhah, pelat bantalan, perlengkapan, cincin, template, jig, sprocket, cam, gir, pelat dasar, tempa, karya hias, pasak, braket, peralatan otomotif lan pertanian, rangka, bagean mesin.